| POWERPOINT |

| PBO SERIES |

| PBO SERIES |

| PBO SERIES |

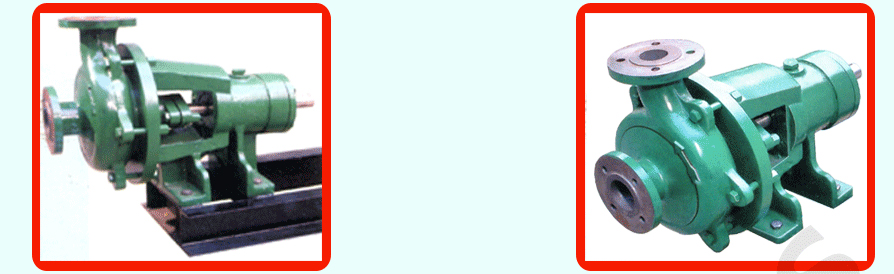

| CHEMICAL PROCESS PUMPS |

| Back Pullout Pumps |

| PBO SERIES |

STANDARD FEATURE

|

VOLUTE CASING

|

Heavy duty casing with integral foot and multi - ribbed discharge flange provides superior resistance to pipe loads and improves reliability. Back pullout design allows for removal of the rotating elements without disturbing the casing pipework of motor to simplify routine maintenance. |

IMPELLER

|

Duplex stainless casted, open Impeller for high efficiency performance, low running cost and long life, impeller back vanes and shroud design provides axial balance which reduces maintenance and downtime cost by extending seal and bearing reliability. |

SHAFT SEAL

|

||||||||

CPP - Series process pumps can be supplied either with gland packing compatible to the pumped liquid or with mechanical seal in the stuffing box having suitable connection / stamping for sealing / slushing / circulation / cooling etc. |

||||||||

APPLICATIONS

|

||||||||

Chemicals, Petrochemicals, Refineries, Suger, Food Stuffs, Paper, dyes, Textilies, Rubber, Environmental Engineering, Handing of Hydrocarbons, Organic and Inorganic Chemicals, Condensate DM Water etc. |

||||||||

RANGE

|

||||||||

|

||||||||

SHAFT

|

||||||||

Made of EN -8 Steel and SS304, SS316 specificaltion, ample size to transmit power without distortion or vibration |

||||||||

BEARINGS

|

||||||||

Antifriction ball bearings, single row deep grooved heavy duty selected to provide maximum service. Oil lubrication arranged by oil point. |

||||||||

STUFFING BOX

|

||||||||

Deep gland box used with graphite packing. Packing are lubricated by lantern ring with grease. |

||||||||

ROTATION

|

||||||||

Marked with arrow on the casing of each pump. Check before coupling with prime mover. |

||||||||

BASE PLATES

|

||||||||

Suitable base can be supplied with the pump. |

||||||||

MATERIAL OF CONSTRUCTION

|

||||||||

C.I. Bronze, SS304, SS316 etc. |